How is a Squeegee Used in the Silkscreen Process?

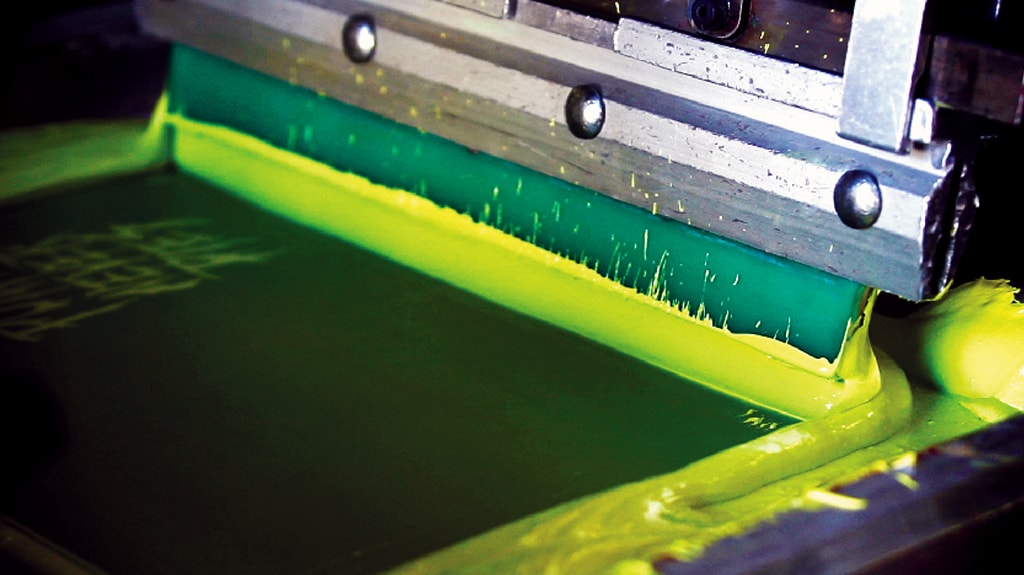

A squeegee is an essential tool in the silkscreening process. The squeegee is used to spread a thin layer of ink over the screen, which will be transferred onto the fabric or paper being printed. It is important that this layer of ink is even and consistent throughout, so it must be moved across with a smooth and steady pressure.

This can often require multiple passes of the squeegee depending on the nature of the design being printed. Additionally, after each pass of the squeegee, any excess ink should be wiped away from both sides of the screen to prevent bleeding into other areas during printing. Proper use and care for your squeegees will help ensure high-quality prints every time they are used in silkscreening projects!

The squeegee is an important tool in the silkscreen process. It is used to spread ink onto a special screen, which has been stretched with a stencil that was created using photo emulsion. The squeegee pushes the ink through the mesh of the screen so it can be transferred to the material being printed on.

By controlling pressure and angle of attack, one can control how much ink passes through and create more intricate designs than would be possible without this tool.

Credit: www.freepik.com

What is the Function of a Squeegee?

A squeegee is a tool commonly used in the printing, cleaning and window washing industries. It is designed with a rubber blade attached to a handle, allowing for even pressure when wiping down surfaces. The rubber blade allows for an efficient removal of water, dirt and debris from glass, walls and other hard surfaces.

Squeegees can also be used for applying sealants or adhesives to surfaces such as tiles or windowsills. In addition to its cleaning application, the squeegee tool can also be used to apply paints and coatings on various materials including wood, metal, plastic and drywall.

What Process is Used in Silkscreen?

Silkscreening (also known as screen printing) is a process used to print images and designs onto various materials. The process begins with a mesh transparencies that acts as a stencil for the design. Ink is then applied to the mesh, which only passes through certain areas of it to create an image on whatever material is being printed upon.

After this step, the ink must be cured either through air drying or heat-setting in order for it to become permanent on the fabric or other substrate. Silkscreening can produce vibrant and long lasting prints when done correctly and offers more flexibility than traditional methods of printing such as letterpress or engraving.

Which Printing Process Uses a Squeegee?

Screen printing is one of the most commonly used printing processes, and it utilizes a squeegee for the application of inks onto various materials. The process requires a stencil to be created with areas that will accept ink and those that will not. This stencil is then placed on top of a screen, which is made from mesh fabric stretched tightly over a frame.

Ink is then applied to the top side of the screen using either an automated or manual squeegee system. As the squeegee passes across the surface, ink pushes through holes in the stencil and transfers directly onto whatever material may be underneath. Once this step has been completed, heat can be applied to cure or fixate any printed designs onto their intended substrate.

HOW TO PROPERLY USE SQUEEGEE IN SCREEN PRINTING – SILKSCREEN PRINTING TUTORIALS

What Stencil Problem Did the Silkscreen Process Solve

The silkscreen process was an innovative and efficient solution to the stencil problem that had been plaguing printmakers for centuries. Unlike traditional printing methods, which relied on hand-cut metal or wood blocks with pre-carved images, the silkscreen process allowed users to quickly create prints using a single piece of fabric as their template. By simply affixing this fabric onto a frame and pouring ink directly over it, they were able to make multiple copies of their artwork in relatively little time.

This revolutionized commercial printing and enabled artists around the world to easily produce high-quality graphics on a large scale without having to worry about tedious stencil cutting processes.

Conclusion

Overall, a squeegee is an essential tool in the silkscreen process. It helps to distribute and spread ink evenly across a surface, resulting in a beautiful and professional final product. With proper use of this helpful tool, you can be sure that your designs will look great every time.