How to Clean Screen Printing Squeegee?

Screen printing squeegees can be cleaned by using a cleaning solution, such as a degreaser or screen opener. To begin, use a cloth to wipe off any excess ink on the squeegee. Next, mix the cleaning solution with warm water and submerge the squeegee in it for 10-15 minutes.

Once done, rinse with clean water and allow to air dry completely before using again. Before using the squeegee again you may need to sharpen it up depending on how much wear has occurred during its last usage. This is done by running an emery board along both sides of the blade which will help restore its edge for further use.

- Gather Supplies: Before beginning to clean the squeegee, gather a bucket of warm water, dish soap or mild detergent, and a soft cloth or sponge

- Dip in Water: Dip the squeegee into the warm water and let it soak for several minutes

- This will help loosen any tough residue that has built up on its surface over time

- Scrub with Soap/Detergent: After soaking, use a soft cloth or sponge to scrub away any remaining residue using either dish soap or mild detergent as needed

- Make sure to rinse off all of the soapy suds afterward with plenty of warm water before drying thoroughly with a different cloth or paper towel

- 4

- Dry Squeegee Thoroughly: Once all residue is removed from the squeegee’s surface, dry it off completely using another clean cloth or paper towel before storing away until next use

Credit: www.anthemprintingsf.com

How Do You Clean a Squeegee?

When cleaning a squeegee, it is important to start by removing any debris that may be stuck on the rubber blade. This can be done by running the squeegee under warm water and using your fingertips to dislodge any dirt or grime. Once you have removed all of the debris, fill a bucket with warm soapy water and submerge the squeegee in it for about five minutes.

After this time has passed, use an old toothbrush or sponge to gently scrub away any remaining residue from the blade. Rinse off your squeegee with clean water once completed and then lay flat to dry before storing away until next use.

How Do You Clean Screen Printing Tools?

Screen printing tools need to be cleaned regularly in order to keep them in top condition. The best way to clean these tools is by using a mild detergent, warm water and a soft brush or cloth. Make sure you scrub away all ink residue.

Rinse the area with clean water afterwards and let it dry thoroughly before storing the equipment away. To ensure a thorough cleaning, consider investing in specialized screen-printing cleaning solutions designed specifically for this purpose. In addition, make sure your workspace is always free from dirt and dust as this can contribute to build up on your tools over time and ultimately impede their performance.

What Can I Use As a Squeegee for Screen Printing?

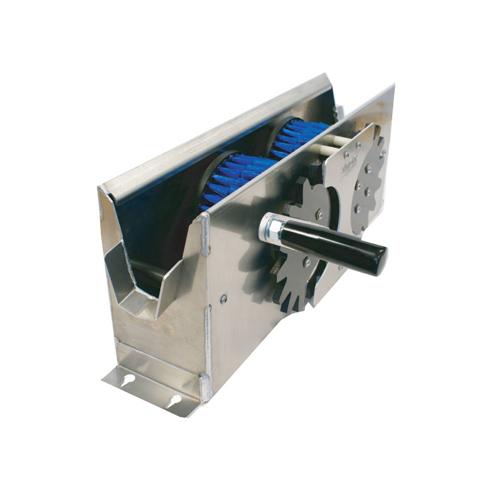

A squeegee is an essential tool for screen printing, as it helps to evenly push ink through the screen and onto the substrate. When selecting a squeegee for screen printing, there are several factors to consider such as blade size, durometer (hardness), angle of cut, and handle type. The most common materials used for squeegees include rubber blades with either metal or plastic handles.

For general purpose use in manual printing applications, a 70-durometer rubber blade with an 8” angled cut and wooden handle works great. For more demanding applications such as automated presses or higher production runs where speed is important, harder 100-durometer rubber with longer 10” angled cuts work better because they hold up better over time when exposed to high pressure and heat from automated presses. Whatever your needs may be, make sure you get a quality product that will last you through many print jobs!

How Many Times Can You Reuse a Silk Screen?

Silk screening is an incredibly durable medium and can be reused multiple times. Generally, the number of uses depends on how well you take care of your screens in between printing sessions. With proper cleaning and storage, silk screens can last for up to a hundred prints or more – some professionals report even higher numbers.

If you are using a wooden frame, however, it may need to be replaced at some point due to wear and tear from the stretching process over time. It’s important to check regularly for any rips or tears in your screen that could affect its longevity as well.

How To Screen Print: Cleaning & Maintaining Squeegee Tips

Silk Screen Cleaning Solvent

Silk screen cleaning solvent is a specialized cleaner designed to remove ink residue, oils, and other solids from silk screens used in the printing process. It can be composed of various organic or non-organic compounds such as petroleum distillates, alcohols, acetone, kerosene and glycol ethers depending on the specific needs of the fabricator. Silk screen cleaning solvent is an essential part of the printing process as it helps ensure that your prints are clean and clear without any residual contamination.

Conclusion

In conclusion, cleaning your screen printing squeegee is an important maintenance task for ensuring that the quality of your prints remains at a high level. As shown in this blog post, there are several steps you can take to ensure that your squeegee is properly cleaned and maintained. Taking the time to clean and care for your equipment will ultimately result in better quality prints and help extend the life of your screen printing supplies.